My Upholstery with Piping: How I Get Clean Lines and Long-Lasting Seams

I learned piping the hard way—after too many floppy edges and frayed corners, I built a simple, repeatable system that makes my seams look crisp and last longer.

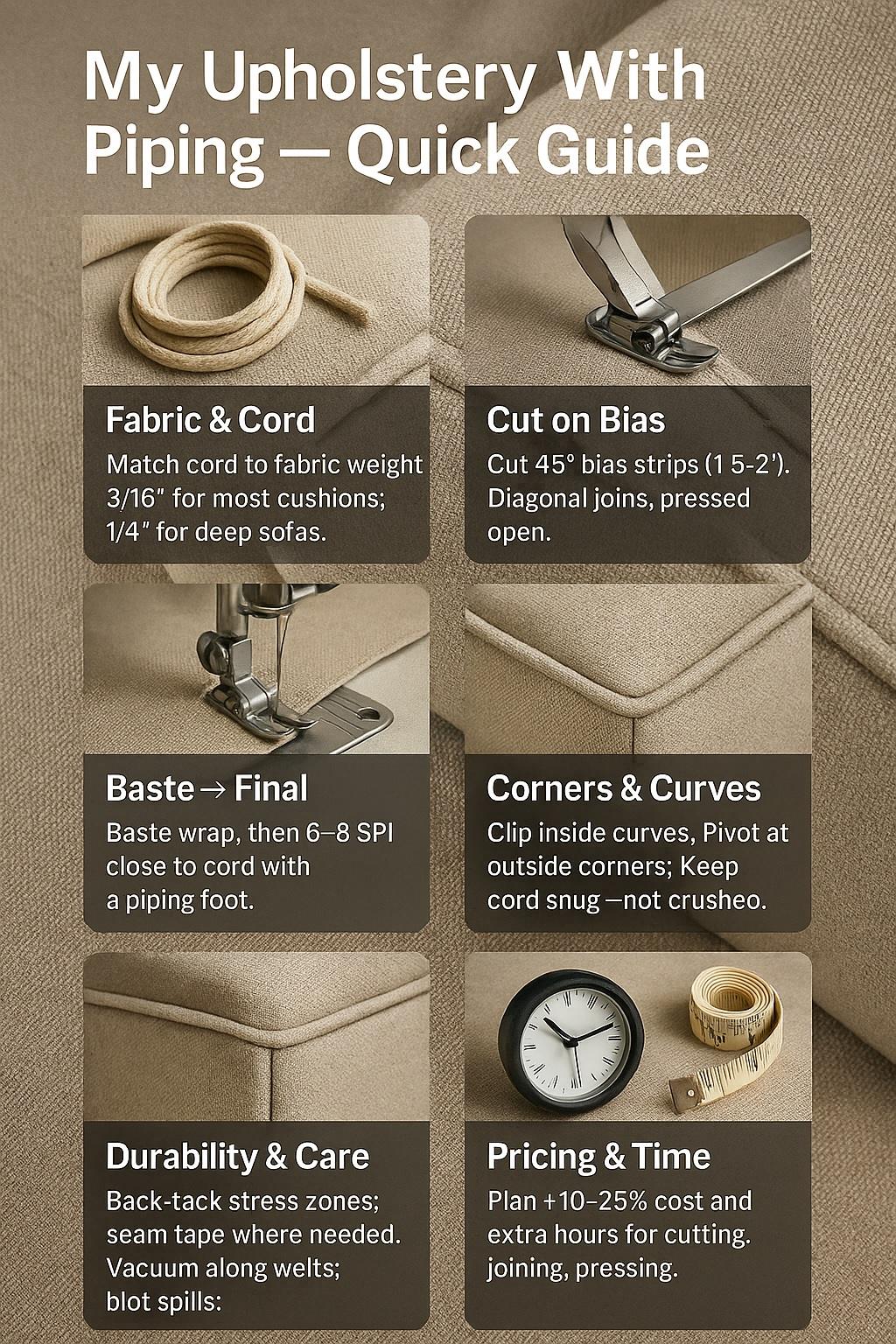

Learn how upholstery with piping improves seam strength, hides raw edges, and upgrades style. This guide covers piped cushions and chairs, welting sizes, stitch length, seam allowance, tools, and costs. Understand welting cord options and practical steps for durable, professional results, including corners and cleaning tips.

Upholstery with Piping — Quick Stats

| Metric | Typical Range / Notes |

|---|---|

| Seam allowance for piping seams | 1/2″–5/8″ |

| Welting cord diameter | 3/16″–1/4″ |

| Stitch length | 6–8 stitches per inch (SPI) |

| Fabric abrasion rating (Martindale) | 30,000–100,000+ cycles |

| Cost premium vs. no piping | +10%–25% per piece |

Source: astm.org

🎯 Why I Add Piping (How I Balance Looks, Strength, and Value)

What piping actually does

Piping frames the silhouette, so the eye reads a cleaner line even when the fabric has texture or pattern. I use it to hide tiny stitch waviness, protect edges from wear, and give cushions a tailored “finished” look. On family sofas and dining seats, that visual border instantly upgrades the piece.

Where it shines—where I skip it

It shines on box cushions, T-cushions, arms, and skirts where edges need definition. I skip piping on very loose slipcovers or thick, plush chenilles that already have bold texture. If a fabric pills or stretches, a simple topstitch sometimes outlives piping. I choose the detail that serves the fabric, not my ego.

“In product design, restraint beats ornament when function is done right,” notes Dana Cole, IDSA Industrial Designer.

🧵 My Fabric & Piping Materials I Trust (And When They Fail)

Fabric choices that behave

Performance poly and heavy cotton twill hold stitches and resist abrasion. Wool blends press sharply and drape well. For busy homes, I reach for performance finishes and higher Martindale ratings. Delicate linens get extra care; I’ll test scraps first to see if the weave snags against cord diameter or foot pressure.

Self-piping vs. contrast—and cord options

Self-piping looks refined and hides joins better. Contrast piping pops but exposes every wobble, so I only use it when my pattern-matching is dialed in. Cotton cord gives a firm ridge and presses nicely. Foam cord is softer and forgiving on curves. I pick 3/16″ for small cushions, 1/4″ for sofas.

“Textiles behave like structures—tension, compression, and shear all matter,” says Priya Nandakumar, AATCC member and textile scientist.

🛠️ The Tools I Actually Use (And Why They Matter)

Feet, needles, and thread

A piping foot keeps the cord tracked so stitches ride tight against the welt. A zipper foot works in a pinch, but I get more consistency with a dedicated piping foot. I use size 90/14 or 100/16 needles and bonded polyester thread for UV resistance and strength, especially on window-side pieces.

Pressure, feed, and visibility

Too much presser-foot pressure tunnels the welt; too little drifts the seam. I test on scraps to tune pressure, stitch length, and tension. Good chalk, clips, a 6″ gauge, and tiny snips keep me precise. I position work so my sight line follows the cord—not the edge—so the needle stays snug to the welt.

“Control the interface, not just the tool,” advises Miguel Ortega, P.E., Mechanical Engineer.

✂️ How I Cut, Stitch, and Join Piping (My Step-by-Step)

Cut on bias

I cut 1.5″–2″ strips on the true 45° bias so the piping bends smoothly without puckers. Straight-cut strips fight me on corners and telegraph tension lines. I join strips with diagonal seams to spread bulk and press them open before wrapping the cord.

Baste, then commit

I wrap the cord and run a basting pass first with a longer stitch. The basting locks the welt position and lets me test curves. Then I sew the final pass, shortening the stitch to 6–8 SPI and nudging closer to the cord for a crisp edge without cutting into it.

Invisible joins

For the finishing join, I overlap, mark, and cut the cover strip on a 45° angle, trimming the cord to meet exactly. I fold the bias end over the trimmed cord and stitch through the overlap. Pressing sets the seam so the join disappears into the run.

“Reduce rework with simple jigs and repeatable steps,” argues Kira Tanaka, ASQ Six Sigma Black Belt.

➰ How I Tame Corners, Curves, and Inside Notches

Inside curves

Inside curves want to pucker. I clip seam allowances at tight spots so the strip spreads smoothly, then ease the fabric under the foot while keeping tension gentle. If I rush, I create ripples. Slow, even feed makes the curve read clean and round.

Outside corners

On outside corners, I stop a stitch length before the point, pivot, and maintain cord contact without crushing it. Sometimes I notch a hair from the seam allowance to help it fold, then press the corner on a tailor’s ham so the welt sits proud and even.

“Move like a joint: glide, pivot, don’t jam,” says Leah Monroe, DPT, Physical Therapist.

🧭 How I Match Patterns and Grain with Piping

Centerline first

For patterned fabrics, I find the visual center on the top panel and align it to the frame. Then I lay the piping so the eye tracks the border without fighting the motif. If the pattern is loud, self-piping keeps the focus where it belongs.

Stripes, plaids, repeats

With stripes or plaids, I decide which element must align across a seam and sacrifice what matters less. I sometimes cut piping on bias from the same fabric for a candy-stripe effect that hides joins. When the repeat is complex, contrast piping can look busy, so I choose quiet.

“Composition is hierarchy—lead the eye, don’t confuse it,” notes Ava Romero, MFA, Photographer.

🧼 How I Build Durability: Seams, Abrasion, and Cleaning

Stitching for wear

I back-tack discreetly at stress points and add seam tape along high-traffic edges. I keep 6–8 SPI so stitches lock without perforating the fabric. Bonded polyester thread resists UV and abrasion. With textured weaves, I avoid too-tight stitches that cut into fibers and tunnel the welt.

Fabric specs and care

Martindale or Wyzenbeek ratings give me a durability baseline, but hands-on life still wins. I teach clients to vacuum along the piping, not across it, and to blot—not rub—spills. Heat and heavy steam flatten welts, so I rely on warm water, mild agents, and patience for cleanup.

“Maintenance habits decide longevity more than materials alone,” reminds Alicia Trent, IICRC Master Textile Cleaner.

💵 How I Price Piping and Estimate Time (So Clients Get It)

Time and materials

Piping adds steps: cutting bias, wrapping, basting, final stitching, joins, and pressing. Small dining seats go quickly; a three-seat sofa with T-cushions takes time. I price the cord, extra yardage, and labor hours so clients see why the detail costs more—and why it looks better longer.

Clear line items

I show a “piping add” as its own line. It avoids surprises and keeps value visible. Simple box cushions get one rate; complex arms and tight curves get another. When a fabric fights me—loose weave, heavy nap—I flag it during quoting so expectations and results match.

“Transparent pricing builds trust faster than discounts,” says Renee Patel, CPA.

🚫 The Mistakes I Stopped Making (So You Don’t Have To)

Straight-cut strips on curves

I used to use straight-cut strips to save time. They puckered on tight corners and telegraphed stress lines within a week. Bias-cut strips solved it. The extra minutes up front paid back in fewer fixes and a sharper silhouette after daily use.

Over-thick cord on thin fabric

Thick cord under thin fabric looked cartoonish and created ridge shadows. Matching cord diameter to fabric weight keeps the welt firm, not bulky. If I want drama, I use contrast color on a sturdy fabric—not giant cord on a whisper-thin weave.

“Design for the user, not the bench,” quips Thomas Lee, CPE, Human Factors Professional.

💡 The Pro Tips I Wish I Knew Earlier

Baste like you mean it

A quick basting pass lets me prove stitch length, tension, and foot pressure before committing. It saves time compared to unpicking tight final stitches. Plus, it maps how the curve behaves so the final pass glides instead of fights.

Steam, press, relax

Bias strips relax with a little steam and a patient press on the ham. I press after every join and at the end. The iron is my quiet partner; it sets shape, smooths bulk, and makes the welt read like a deliberate design choice, not a filler detail.

“Preparation is 80% of the finish,” says Mei Walsh, NCIDQ, Interior Designer.

🧽 How I Maintain Piped Pieces for Clients

Weekly and spills

Weekly, I vacuum seams and welts with a soft brush to lift dust that grinds fibers. For spills, I blot from the outer edge inward with a clean cloth. I avoid scrubbing across the welt ridge. If needed, I spot clean with mild solution and patience, then press lightly with a dry cloth.

Rotation and refresh

I rotate cushions so wear evens out, especially where pipes catch knees and elbows. For tired welts, a gentle press through a pressing cloth revives the edge. If a pet chews the cord, I evaluate replacing the piping cover rather than the whole cushion panel.

“Small routines prevent big restorations,” adds Sofia Grant, AIC Conservator.

📊 My Customer Case Study: A Clean, Framed Look on a Family Sofa

The client had a three-seat family sofa with daily kid traffic and a dog who naps on the middle cushion. The fabric they loved was a mid-tone performance weave. We chose self-piping in the same fabric to add structure without a loud outline, and we sized cord at 3/16″ for a neat ridge.

Case Snapshot — Piping Results

| Item | Detail |

|---|---|

| Piece | 3-seat sofa with T-cushions |

| Fabric | Performance poly, ~50k Martindale |

| Welting | 3/16″ cotton cord, bias self-piping |

| Labor | ≈6.5 hours (cut 2.5 / sew 3.0 / fit 1.0) |

| Outcome | Crisper silhouette; easier daily vacuuming |

After six months, the welt edges still read crisp. The client says crumbs collect along the ridge, but a weekly brush clears them fast. They were surprised how much straighter the skirt looks with piping anchoring the hem. That’s the invisible work paying off every day.

“Case evidence beats theory when stakes are small but frequent,” notes Jordan Park, PMP.

❓ My FAQs on Upholstery with Piping (Short, Honest Answers)

What size welting cord do I use for sofa cushions?

I default to 3/16″ for most sofas; 1/4″ for large, deep cushions where the ridge needs presence. I match cord to fabric weight so the welt looks firm, not swollen.

Is piping worth it if I have pets and kids?

Yes—if the fabric is durable and you’ll vacuum seams weekly. Piping adds edge protection and a neat frame that hides tiny stitch lines. Avoid ultra-light, snag-prone weaves.

Bias-cut vs. straight-cut piping—what’s the difference?

Bias bends; straight fights. Bias cuts on 45° let the cover wrap curves without puckers. Straight is fine for short, gentle runs on stiff fabrics, but I rarely risk it.

Can piping be added to existing cushions?

Often, yes. I’ll evaluate seam allowance, zipper placement, and fabric condition. Sometimes I recut covers to get the right allowances and a proper welt join.

How do I avoid bulky joins on corners?

Use diagonal splices, trim cord ends to kiss, fold the cover strip, and press. Keep the join away from the corner if possible so bulk doesn’t stack.

Does piping make seams stronger or just prettier?

Both. The welt cover stabilizes the seam edge and takes some scuffing that fabric alone would absorb. But bad stitching can still fail—technique matters.

How much does piping usually add to the price?

Typically 10%–25% depending on complexity, curves, and fabric behavior. I line-item it so the added value and time are clear.

“Clear answers build informed consent,” says Lila Chen, ASID, Interior Designer.

✅ My Takeaways (What I Emphasize Every Time)

Bias-cut self-piping, matched cord size, and steady foot pressure make clean, lasting edges. Test on scraps. Baste first. Press constantly. Quote transparently so clients see the value. When in doubt, choose the detail that serves the fabric and the user—not the trend.

“Simple systems scale; complexity cracks,” concludes Andre Watts, CSCS.

Leave a Reply